For PCB printed circuit board drilling, the upper and lower backing plates are used to prevent the copper foil on the surface and bottom of the circuit board from blooming and generating burrs, so as to make the drilling surface of the circuit board smooth, improve the quality of PCB printed circuit board and improve the yield. The use of this auxiliary material has a certain cost, but it is actually needed for the above reasons, which can greatly improve the product qualification rate and reduce the cost.

The requirements of the upper backing plate for the circuit board drilling are that it has a certain surface hardness to prevent burr on the upper surface of the drilling. But not too hard to wear the drill bit. It is required that the resin composition of the upper and lower base plates should not be too high, otherwise molten resin balls will be formed and adhered to the hole wall during drilling. The larger the thermal conductivity, the better, so that the heat generated during drilling can be quickly taken away, the temperature of the drill bit during drilling can be reduced, and the drill bit can be prevented from annealing. It must have certain rigidity to prevent the plate from vibrating when lifting the drill, and also have certain elasticity to immediately deform when the drill bit is in contact with the drill, so that the drill bit can accurately align with the position to be drilled and ensure the accuracy of the drilling position. The material shall be uniform and there shall be no impurities to produce uneven soft and hard nodes, otherwise the drill bit will be easily broken. If the surface of the upper backing plate is hard and slippery, the small-diameter drill bit may slip and deviate from the original hole position to drill elliptical inclined holes on the circuit board.

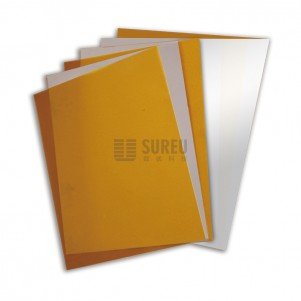

The upper backing plate used in China is mainly 0.2-0.5mm thick phenolic paper adhesive plate, epoxy glass cloth plate and aluminum foil, such as lf2y2 (No. 2 antirust aluminum semi cold working hardening state) or lf21y (No. 21 antirust aluminum cold working hardening state) with a thickness of 0.3mm. It is effective as the upper backing plate for common double-sided plate drilling, and the hardness is appropriate to prevent burr on the surface of drilling. Due to the good thermal conductivity, rigidity and elasticity of aluminum, it has a certain heat dissipation effect on the drill bit. The material of aluminum foil is more uniform than that of phenolic plate, and there is no impurity. The probability of breaking the drill bit and eccentric hole is greater than that of phenolic plate. It can reduce the drilling temperature and is an environmental protection material. It is widely used. Many factories have used aluminum foil as the upper backing plate. Meanwhile, compared with phenolic plate and epoxy plate, the hole may not be polluted by the resin because of the resin contained. The thickness of the commonly used aluminum foil is 0.15, 0.20 and 0.30 mm. In the actual use process, 0.15 has good contact with the plate surface, However, it is difficult to control the process during cutting, transportation and use. The price of 0.30 is a little higher. Generally, 0.20 mm aluminum foil is used in a compromise, and the actual thickness is generally 0.18 mm.

There is a composite upper backing plate abroad. The upper and lower layers are 0.06mm aluminum alloy foil, and the middle layer is a pure fiber core with a total thickness of 0.35mm. It is not difficult to see that this structure and material can meet the requirements of PCB printed circuit board drilling upper backing plate. It is used for high-quality multi-layer board upper backing plate. Compared with aluminum foil, its advantages are: high drilling quality, high hole position accuracy, improved drill life due to small wear, and the plate is much better than aluminum foil in returning to its original shape after being subjected to external force, and its weight is also much lighter. It is especially suitable for drilling small holes.

The lower backing plates used in China include phenolic paper board, cardboard and wood chip board. The paperboard is soft and easy to produce burrs, but the texture is uniform and it is not easy to break the drill bit and bite the drill bit. However, it is cheap and can be used in thin copper foil or single panel. The wood chip board has poor texture uniformity and better hardness than the paper board. However, if the copper foil of the circuit board is larger than 35 microns, burrs will be generated. I tried to use the board to drill the double-sided board with 70 microns copper foil, and the results were all unacceptable. The hardness uniformity of phenolic paper board is between the former two, and the use effect is good, but it is expensive and environmentally friendly.

Similarly, there is a composite lower backing plate abroad. The upper and lower layers are 0.06mm aluminum alloy foils, and the middle layer is a pure fiber core with a total thickness of 1.50mm. Of course, it has excellent performance and environmental protection, which greatly exceeds the phenolic paper board. Especially when drilling multi-layer boards and small-diameter holes, it can fully reflect its advantages, but the disadvantages are of course expensive.